DIMENSION COMPONENTS

DIMENSION COMPONENTS

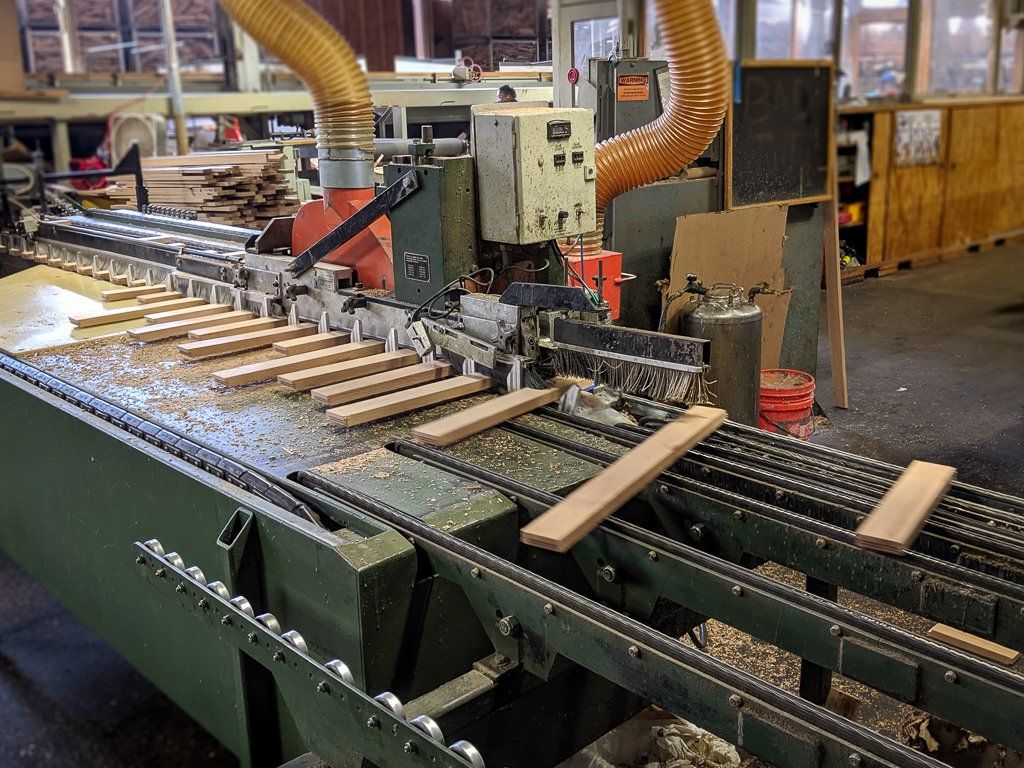

Although Anderson Wood can supply dimension blanks, most customers prefer to buy value added parts. Moulding, tenoning, profile sanding, boring and mortising; these and many other woodworking capabilities allow Anderson’s experienced staff to provide our customers with products that meet their unique specifications and needs. Our ability to assemble and pre-finish the components we produce allows us to take products to the next level and create greater value for our customers.

Lumber is sourced from sustainable hardwood forests as verified by the US Forest Service. Anderson operates our own kilns to control drying and moisture content. Our state-of-the-art Rough Mill utilizes vision systems and computer optimization to maximize yield while efficiently cutting at high volumes. We provide a wide array of products including handrail and associated stair parts, edge glued panels, laminated posts, stiles, rails and other machined parts. Anderson Wood is the largest American manufacturer of both hardwood dormitory bed ends and of stair railing. We are committed to meeting our customers’ needs and readily align equipment and processes to meet special requirements or create economies.

OUR CAPABILITIES INCLUDE

- Finger-Jointing

- Edge Gluing

- Lamination

- Flat Sanding

- Edge Sanding

- Moulding

- Face Boring

- Edge and End Boring

- Profile Shaping & Sanding

- End Work (Coping, Mitering)

- Doweling

- Mortising

- Assembly & Finishing

- Routing (CNC & Overhead)

- Tenoning (Rotary & Conventional)

SUSTAINABLE AMERICAN HARDWOOD PRODUCTS SINCE 1906

All Rights Reserved | Anderson Wood Products Company | Powered By RankingCo